A Global Semiconductor Shortage

Expensive cars? Phone order delays? Learn how today’s globalized supply chain can affect our daily lives by exploring the global semiconductor shortage.

Here’s a riddle: What tiny device has delayed the release of cars, phones, and even blood pressure monitors ? Did you guess computer chips, otherwise known as “microchips”?

What are semiconductors?

Although you probably don’t hear about them often, microchips, also known as semiconductors, are an essential component of millions of products in the modern world.

But in the past few years, semiconductors have been in short supply, resulting in production delays across many industries. What caused those shortages?

What caused the semiconductor shortage?

Most disruptions in the supply chain have more than one culprit, and a challenge that can affect daily purchases in the United States has crossed multiple country borders.

The initial shortage was caused by the COVID-19 pandemic. Across the world, people called in sick, frequently missing days or weeks of work. Some countries started instituting lockdowns and quarantine policies to fight the virus, which left microchip factories in places like the E.U, Japan, South Korea, Taiwan, and the U.S. understaffed or completely closed. That delay in microchip production ultimately had ripple effects on the supply chains of the products that used them.

At the same time, pandemic shopping lists filled with items that required microchips: laptops for kids attending school on Zoom, Xboxes and televisions to pass time during quarantine, and phones to FaceTime friends and family while locked down. In short, the pandemic lowered supply and increased demand for microchips, leading to a shortage of products and, sometimes, higher prices.

In 2022, a second factor began aggravating the shortage—conflict in Ukraine. Before the war, half of the world’s semiconductor-grade neon gas, an essential microchip component, was produced by two major companies in Ukraine. As Russian troops began escalating their attacks in the country, both firms were forced to halt operations.

In today’s globalized world, local problems frequently become global. A strike in Germany could cause delays in the delivery of medicine to Mexico, and a storm in Indonesia could mean fewer cars on the lot in Nebraska. The world’s supply chains are longer than ever before, making people more reliant on each other.

Supply Chain Example

The effects of global supply chain disruptions

The recent semiconductor shortage isn’t some far-off issue—it affects everyday citizens around the globe. The shortage has spurred changes across sectors and issues internationally, such as delayed smartphone production and new defensive trade policy. Let’s take a look at how shifts in the semiconductor trade shape security concerns, price hikes, and human rights issues.

Governments consider microchips an essential good, and because of that, they view controlling microchip production and distribution a matter of critical importance. For this reason, in 2022, the United States instated sweeping blocks on semiconductor exports to China. The idea was that the Joe Biden administration’s block could inhibit Chinese technological development, preserving the United States’ leg up on economic and technological advancement. And by prohibiting the export of cutting-edge chips, the United States could undercut China’s development of advanced military equipment. So although many people assume those tiny chips are only used to power smartphones, their availability has geopolitical and security implications.

Considering the importance of microchips, the United States, China, and Europe aim to be self-sufficient in their development. Some experts describe that aim as a country’s push for technological sovereignty. Currently, Taiwan produces 92 percent of advanced logic chips, while the United States only accounts for 6 to 9 percent of mature logic chips.

“We also need a resilient supply chains of our own so that we’re never at the mercy of other countries for critical goods ever again.”

But some experts argue that Biden’s push for supply-chain sovereignty is based on an overstated fear: as of 2022, 92 percent of the microchip supply is controlled by the United States and its allies.

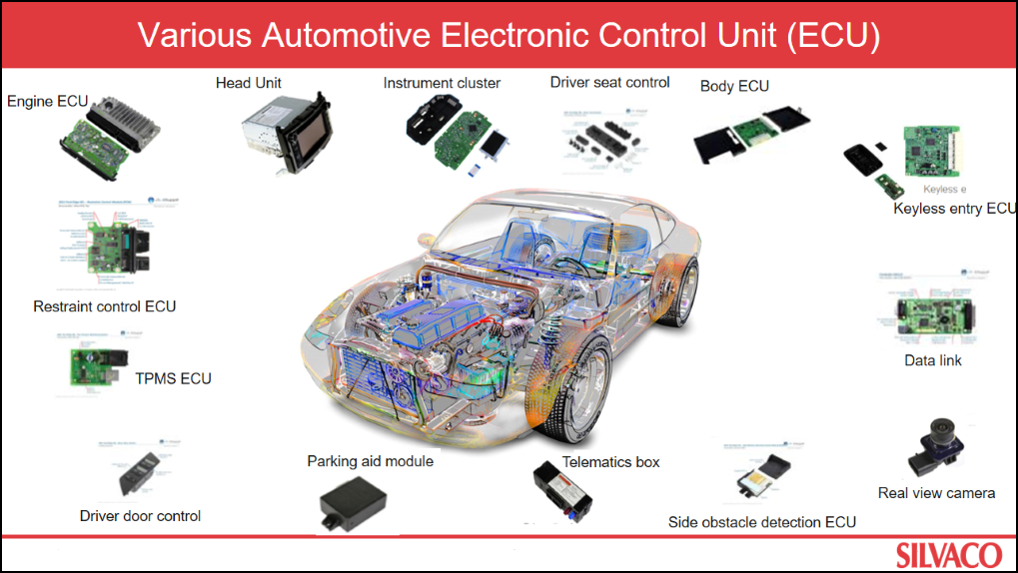

Geopolitics isn’t the only thing affected by the microchip supply—the semiconductor shortage has increased the price of many goods. The average price of a car increased over 15 percent in less than two years because of chip shortages. It may sounds surprising that small chips could make such a big difference, but today’s average car uses one hundred microchips or more.

That price increase hurts not only individual pocketbooks, but also has ramifications for countries’ economies and the world at large. The microchip shortage cost the U.S. economy an estimated $240 billion in 2021. Nearly eight million cars were not produced because they lacked chips.

Supply-chain challenges can yield price hikes for the consumer and lost jobs for manufacturers. Companies laid off thousands of workers because the United States lacked chips. And in today’s global economy, working conditions abroad are not isolated from working conditions at home.

Solutions to the global semiconductor shortage

Various solutions have been put forward to address the shortage of microchips around the world.

One prominent idea is producing chips domestically or nationalizing supply chains. The obvious benefit of focusing on domestic production, or “sovereign supply chains,” is securing stabler access to microchips and other critical goods. Drawbacks include eliminating international competition, which could reduce costs and efficiency. Multiple countries have taken steps toward more sovereign supply chains. The Biden administration has moved toward technological sovereignty through boosts to domestic production such as the CHIPS Act, which put $280 billion toward semiconductor research and manufacturing in the United States.

Europe is similarly seeking chip independence as supply chains are politicized.

Another workaround is developing products that need fewer chips. Some companies have done so by cutting high-tech features from new cars, as well as other chip-intensive features.

A temporary solution is using stockpiled chips. Of course, stockpiles will run out, so this isn’t a tenable solution.

Expanding chip development is perhaps the most uncontroversial method of dealing with the shortage. But making microchips takes time--—and the largest developers of microchips have been in the business for over forty years. Catching up means expanding existing and developing new facilities to increase production capacity.

Finally, developing a more resilient supply chain for the United States and its allies through international pacts could reduce vulnerabilities to China’s growing share of the microchip market. Chip 4, an alliance of the four largest chip manufacturers (the United States, Japan, South Korea, and Taiwan), weakens global reliance on Chinese microchips and supports U.S. and global access to supply.

Microchips will remain an essential good for technology. The recent crisis offers a useful illustration of how isolated changes in the interconnected global economy can cause ripple effects across industries and supply chains around the world. Microchips are but one example of supply-chain disruptions triggering global shortages. Shoring up self-sufficiency not only in the production of and access to microchips, but also in other critical products has implications for economic and national security.