How to Lower Industry-Sector Emissions

Industrial emissions pose big challenges for the climate. Innovative industrial solutions can make a difference.

Making planes and skyscrapers, computers and pharmaceuticals—the products that define life in the modern world—has caused a great deal of climate change. Their manufacture involves industrial products like steel, cement, plastic, and chemicals. Creating those raw materials releases a lot of greenhouse gas. As the world’s population and economy grow, the demand for those products grows as well.

All that production makes up the industrial sector. According to the Intergovernmental Panel on Climate Change (IPCC), it accounts for around 24 percent of global greenhouse gas emissions. So, to tackle climate change, the world urgently needs to develop greener and more sustainable industrial practices.

In this resource, explore how building a greener industrial sector will require many innovative approaches.

How does industry emit greenhouse gases?

Industrial emissions come from several different sources:

- fuel combustion, or burning, which is the chemical process of combining a fuel with oxygen to create extremely high heat for certain industrial processes

- industrial processes, which involve chemical reactions that release greenhouse gases

- waste from humans and industrial processes, which can result in emissions as it is treated and disposed

- indirect emissions from the power plants that provide electricity to run industrial machines and facilities (though the IPCC counts those as energy-sector emissions, they aren’t included in the earlier 24 percent figure)

Addressing indirect industrial emissions involves making the energy sector greener. Countries can lower those indirect emissions by replacing fossil fuel power generation with clean and renewable energy sources. Other types of industrial emissions pose some unique challenges.

Fuel combustion emissions

Many common items that run on gas—like stovetops and cars—can be converted to run on clean electricity relatively easily.

However, running on clean electricity isn’t compatible with certain processes.

Electrical technology is only practical for heating nonconductive materials up to temperatures around 750 degrees Fahrenheit. However, making products like steel and cement requires temperatures near or above 2,000 degrees. It's much easier to achieve that high heat with fossil fuels. That’s why the steel and cement industries typically rely on coal for production, releasing an immense amount of greenhouse gas in the process.

Industrial process emissions

Many industrial processes involve chemical reactions that produce greenhouse gases. Here are some notable examples:

- Steel: Early in the steelmaking process, the coal-based fuel coke is burned to heat up iron ore. At extreme temperatures, the iron ore releases oxygen, which bonds with carbon from the coke, creating carbon dioxide (CO2) as a byproduct.

- Cement: To make cement, limestone (calcium carbonate, or CaCO3) is heated to fierce temperatures. It breaks apart into the cement-precursor product called clinker (calcium oxide, CaO) as well as CO2. That carbon dioxide is then released as a waste gas.

- Ammonia: To grow food, much of the world relies on nitrogen fertilizers. Those fertilizers are produced with ammonia. To make ammonia, producers typically combine natural gas (methane, CH4) with air, which is mostly nitrogen (N2) and oxygen (O2). The elements mix in a special process, creating ammonia (NH3) and a byproduct of CO2.

- Petrochemicals: Many common materials, like plastics, are made using petrochemicals. They are chemical products created from fossil fuels and are often referred to as feedstocks. The production process for different petrochemicals varies, but the chemistry results in methane and carbon dioxide emissions.

- ODS Substitutes: The 1987 Montreal Protocol phased out ozone-depleting substances (ODS). Since then, refrigerants, aerosols, and other items have relied on substitute chemicals—hydrofluorocarbons, perfluorochemicals, and carbon dioxide—that are greenhouse gases, and that are emitted when many such products are manufactured and used.

Waste emissions

Factories inevitably produce trash and byproducts. That industrial waste results in significant greenhouse gas emissions in multiple ways:

- Landfills: As organic waste in landfills decomposes, it releases both carbon dioxide and methane. Other industrial wastes, like plastics, can take thousands of years to break down, but they too can release harmful chemicals over time.

- Incineration: Solid waste is burned to reduce the toxicity and volume sent to a landfill. However, that incineration releases tons of carbon dioxide, methane, and nitrous oxide.

- Wastewater: Industrial processes use water, which retains many types of pollutants. Treating the water to remove those pollutants requires a lot of energy. Depending on how clean the energy sources are, those processes can cause many indirect greenhouse gas emissions. Additionally, the decomposition of organic matter in the wastewater, particularly from human waste products, releases a great deal of methane.

What can be done?

The following new technologies and approaches, among others, can help reduce industrial emissions.

- Hydrogen: This clean fuel doesn’t produce any CO2 when it’s used. Hydrogen burns at high temperatures, and it is easily capable of producing the heat required for many industrial processes like steelmaking. Today, though, most hydrogen is produced from natural gas (emitting CO2). Zero-carbon hydrogen production is still in its infancy as a technology. However, developing it could replace fossil fuels in high heat production facilities and reduce process emissions from ammonia and petrochemical production.

- Electrification: Although electrical heating isn’t suitable for higher-temperature industrial processes yet, advances are being made. Electricity-based techniques could someday be an economically viable replacement for burning fossil fuels. Researchers are also developing ways to use electricity at certain points in steel and cement production to reduce their process emissions as well.

- Carbon capture: Exhaust from burning fossil fuels, chemical reactions, and waste management could be directly filtered, capturing the greenhouse gas. The gas would then be compressed and either reused or permanently stored so it doesn’t get released into the atmosphere. Directly capturing carbon from industrial production is expensive, and it requires using additional energy. Nevertheless, the International Energy Agency projects that carbon capture will play a significant role in reducing industrial emissions in its net-zero emissions scenarios for the next few decades.

- Alternative feedstocks: Fossil fuel–derived petrochemicals could be replaced by other sources. Those include hydrogen, captured CO2, biomass (possibly from agricultural waste), and ethanol, which can be made by fermenting corn.

What's holding us back?

Part of the challenge is that the technology isn’t advanced enough yet. Even in the cases where experts understand how to fully eliminate carbon emission from industrial production, the new technology is not yet commercially viable on a large scale.

Even if scientists had everything figured out, there would still be enormous costs to transitioning industrial operations quickly. Most plants in heavy industry are designed and financed to operate for a long time, typically thirty or forty years. Stopping production to retrofit a plant or shutting it down earlier than expected would likely incur major financial losses for the owners. So, widespread adoption of new emissions-reducing technology in the industrial sector could be relatively slow. In many cases, industrial operators are likely to wait until older equipment wears down before replacing it with newer, low-emissions technology.

What is being done?

Policymakers are directing investment toward the high costs of developing greener industry.

The U.S. Congress provided over $6 billion for the federal Industrial Demonstrations program. The program uses that money to help fund industrial projects that could demonstrate the commercial viability of new low-emissions technology and production processes. All thirty-three projects the program supports are in the United States. They feature a diverse array of green advances—incorporating hydrogen, electricity, and biomass. They also include finding lower-emission inputs and novel ways of capturing and storing carbon dioxide.

New technology isn’t the only answer, though.

Many governments are encouraging the formation of eco-industrial parks. Those are locations where different manufacturers cluster together and share resources, allowing for greater economic and environmental efficiencies. Parks also open up opportunities for the waste from one industrial practice to be used as an input for another manufacturer. For example, at the eco-industrial park in Ulsan, South Korea, steam from an industrial waste incinerator is used to help power a nearby paper mill. Also, wastewater from a different petrochemical plant is used as an input in a sewage treatment facility.

Industrial parks are more common in East Asia. According to the IPCC, China’s more than 200 industrial parks will help avoid 111 million tons of CO2-equivalent emissions in 2030. That’s around the same amount of emissions currently produced by all of Belgium.

Changing how companies make products is an important pathway for reducing emissions. So is changing how people use products. That’s why many experts advocate developing a more circular economy.

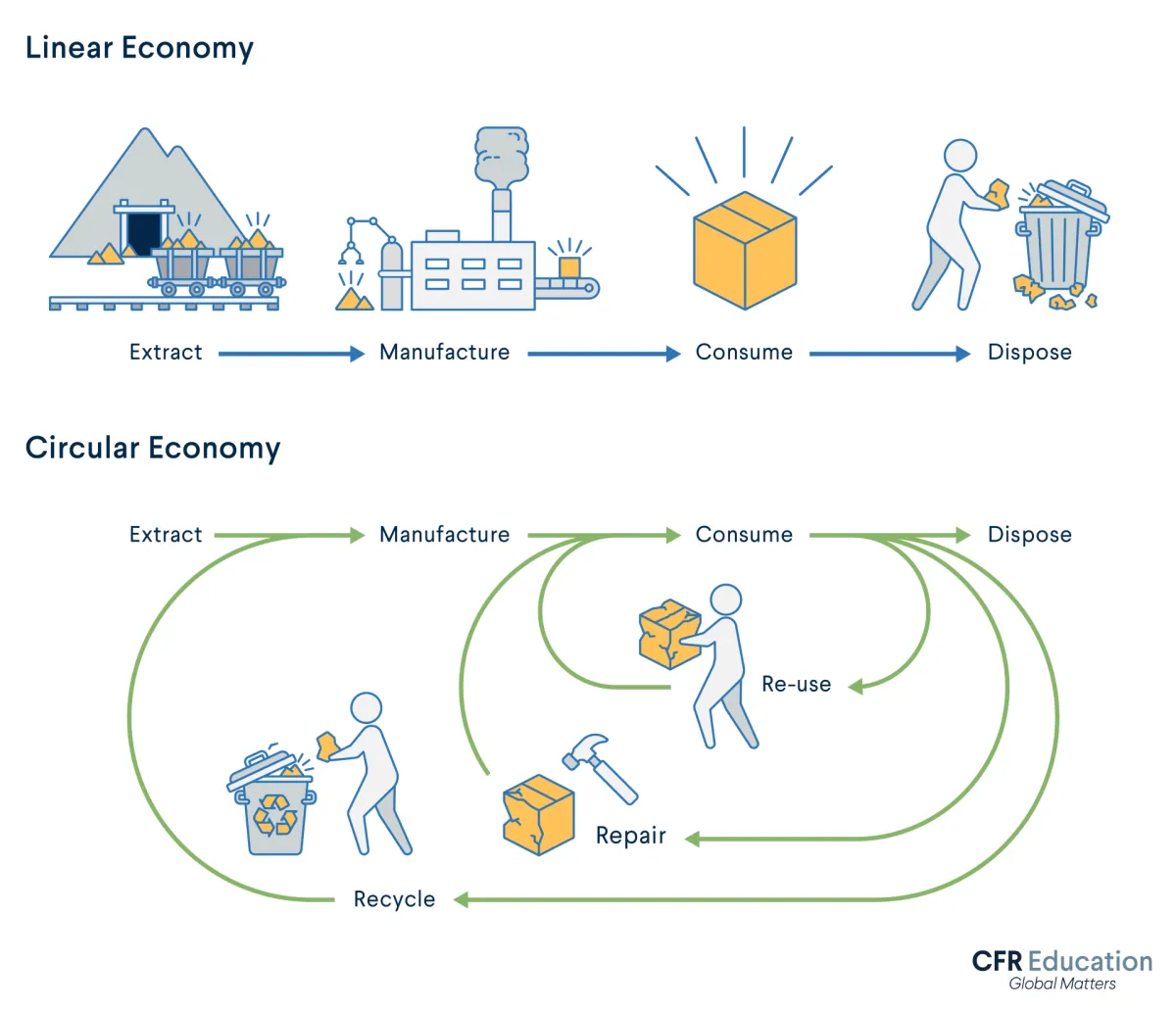

Circular economy strategies would reduce industrial emissions across the board. The idea is that, in the past, humans had relied on a more linear economy. They extracted resources, made products, and then discarded them. With a more circular economy, populations would

- find ways to reduce the number of resources used to create products,

- manufacture products to last longer and be reused multiple times, and

- recycle old products so their components can be used to produce new items.

For example, France recently became the first European country to enact a policy initiative that promotes repairing and reusing existing material products. The French government introduced repair and durability ratings, which help consumers buy durable products and repair and reuse them, cutting down emissions involved in production. That work has spurred efforts such as the European Union’s Sustainable Products Initiative. The initiative promotes the production of more durable and energy-efficient products, including cement and chemicals.

Industry plays a major role in today’s economy, and components like steel and plastic are essential to many aspects of modern living. Yet the emissions they cause are contributing to climate change, jeopardizing the lives of those who make and use what industry produces. Policies and innovations that work to lessen the climate blow from the industry sector will be critical to a more secure and sustainable future.