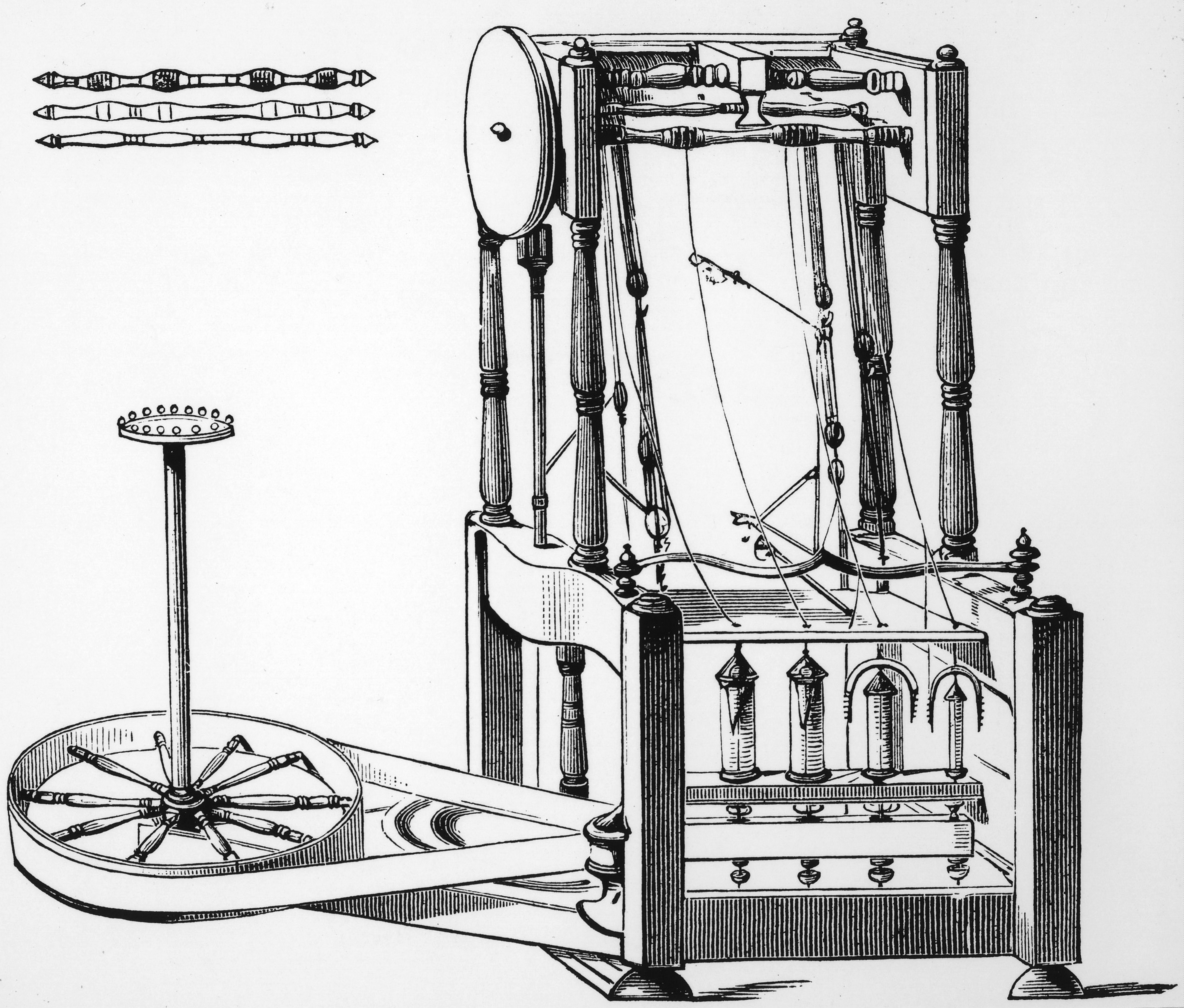

Water Frame

A diagram of the water frame developed by Richard Arkwright.

Source: Universal Images via Getty Images

During the late eighteenth century, as textile manufacturing boomed, inventors engineered multiple improvements on the spinning wheel. One such innovation, the water frame, used running water to both accelerate the pace of textile production and produce cotton yarn that was finer and more durable for weaving. Sir Richard Arkwright patented the machine in 1769, transforming the English textile industry.

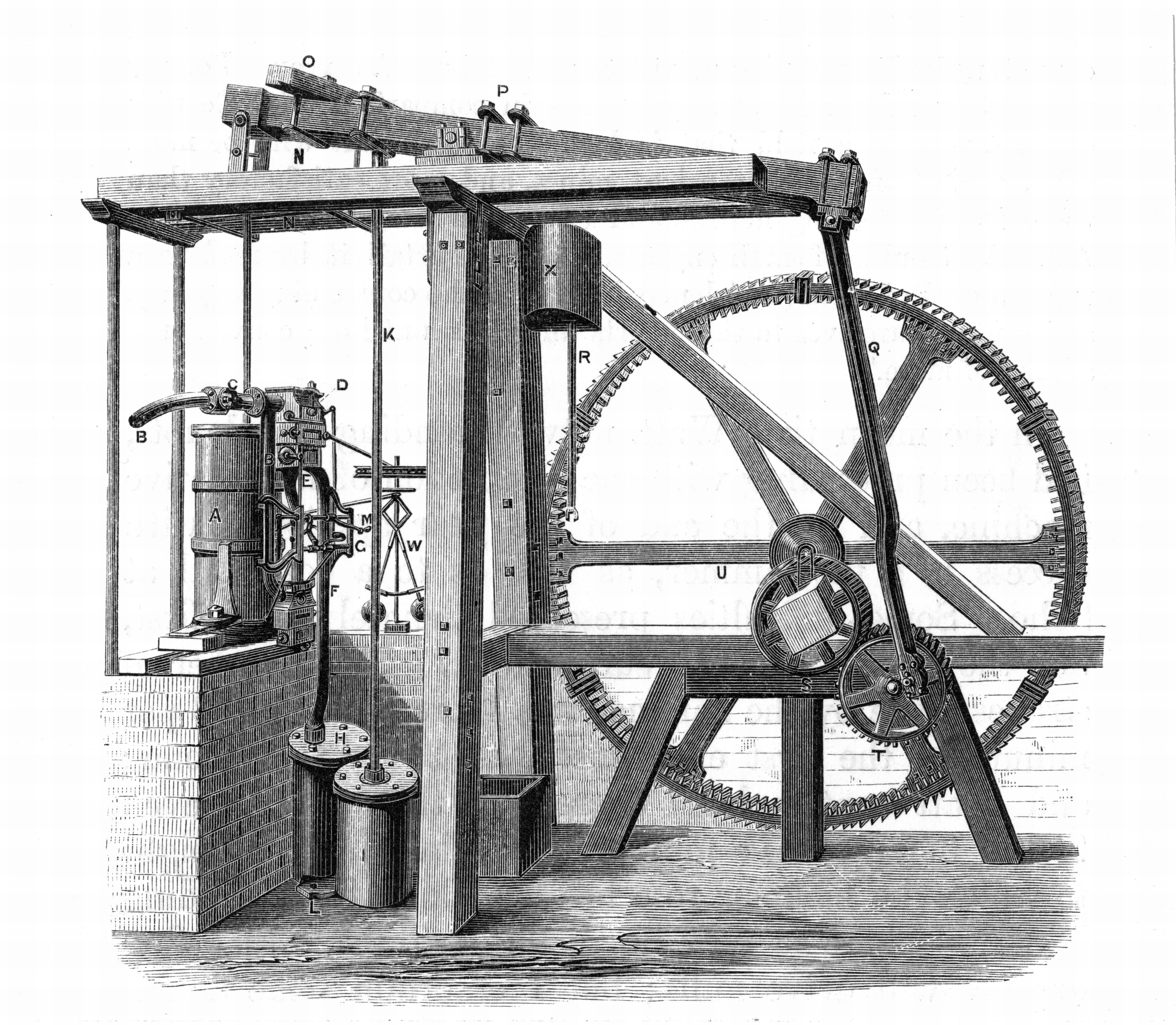

Watt Steam Engine

An engraving of the prototype steam engine developed by James Watt.

Source: Universal Images via Getty Images

Thomas Newcomen invented the first steam engine in 1711. Five decades later, James Watt improved upon Newcomen’s creation, devising a new, highly efficient engine that became a cornerstone of industrialization. Steam-powered machinery dominated manufacturing, agriculture, and transportation industries, increasing productivity and growth.

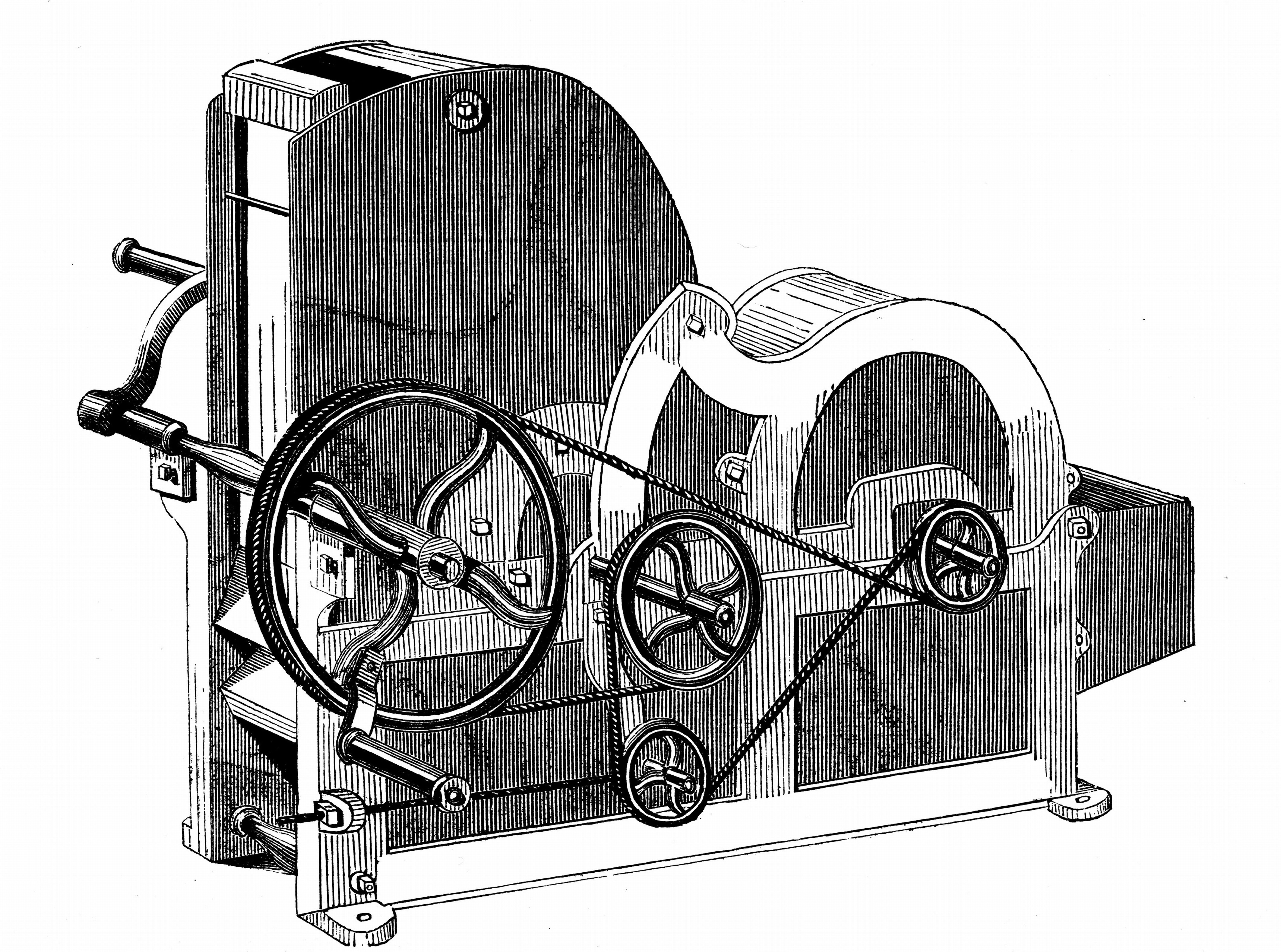

Cotton Gin

An engraving of the saw-gin for cleaning cotton developed by Elihu Whitney.

Source: Universal Images via Getty Images

For thousands of years, farmers manually separated seeds from cotton fiber after harvesting the crop. The process was time consuming and labor intensive. But in 1793, Eli Whitney invented the cotton gin, which automated this cleaning process. The cotton gin—much like the water frame—made textile manufacturing faster and cheaper than ever before. Global demand for cotton soared after its invention, which also increased demand for enslaved people who harvested cotton.

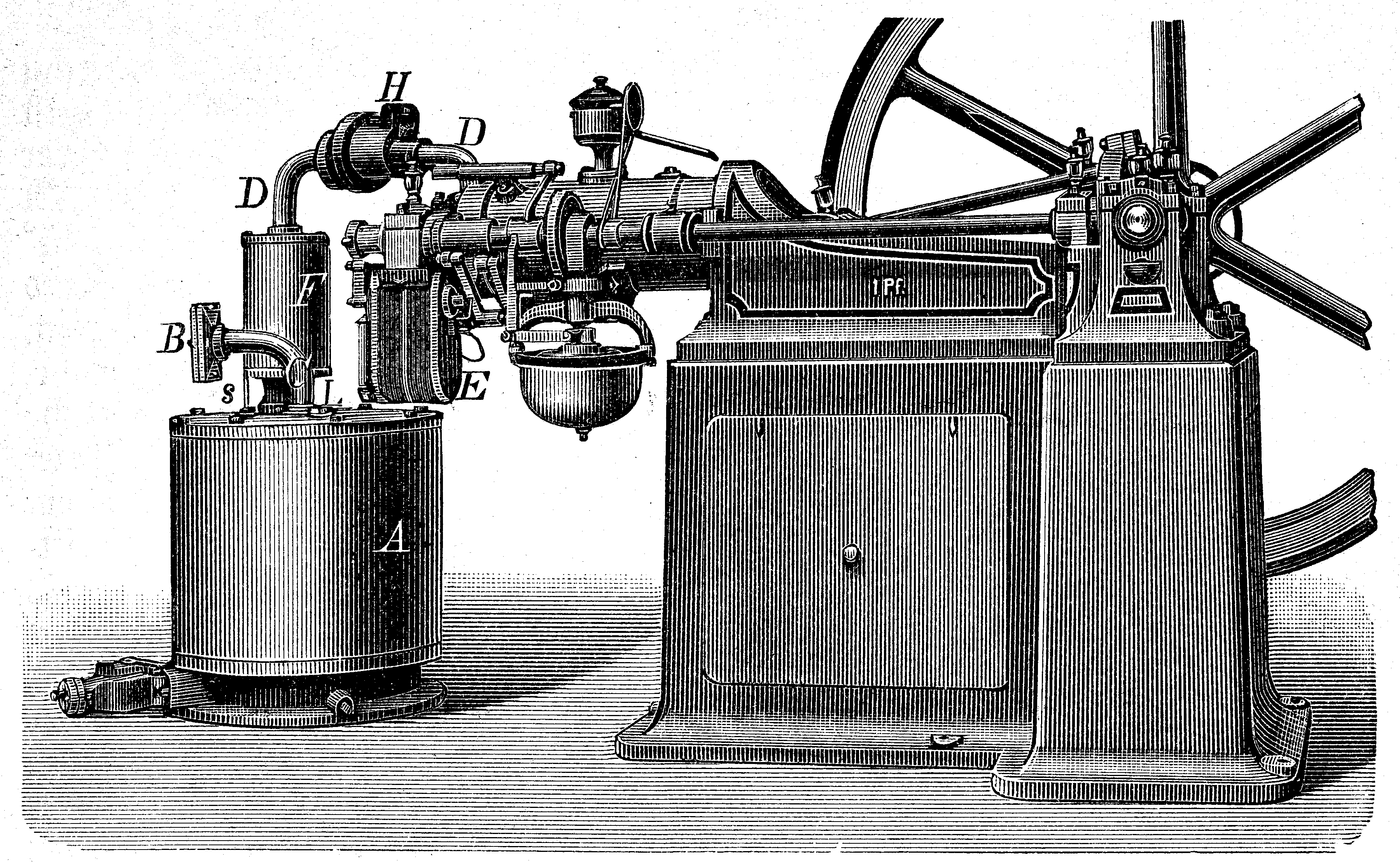

Internal Combustion Engine

A diagram of the internal combustion engine developed by Nikolaus Otto.

Source: Universal Images via Getty Images

The first alternative to the steam engine emerged in Europe in the mid-nineteenth century when engineers Alphonse Beau de Rochas and Nikolaus Otto separately built and patented internal combustion engines. The machines created power through pistons, which sparked the compressed fuel stored in a cylinder. Engineers still use this design today to power cars and motorcycles.

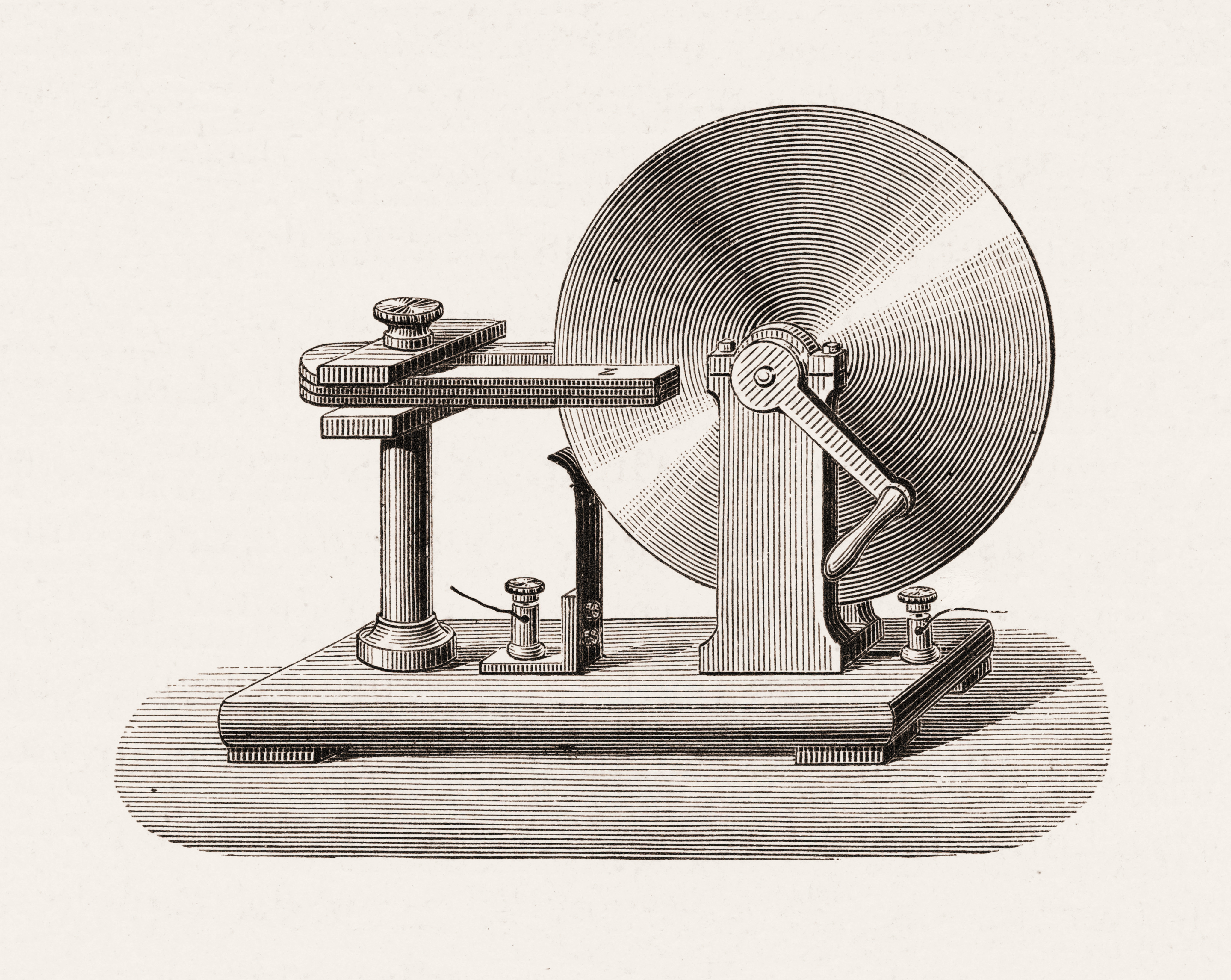

Electric Generator

A diagram of a research laboratory apparatus similar to the type electric generator developed by Michael Faraday.

Source: Stock Montage via Getty Images

In 1830, English physicist Michael Faraday invented the first electric generator. His machine used magnets to create electric currents. In following years, various inventors including Samuel Morse used Faraday’s generator to create another landmark apparatus—the telegraph, one of the earliest text-messaging devices.

Moving Assembly Line

Men on an assembly line work on Ford generators in a small plant at Ypsilanti, Michigan, about 2.5 miles from Dearborn.

Source: Bettmann Archive via Getty Images

In 1913, Henry Ford pioneered the moving assembly in his car factories, using conveyor belts to transport component parts across different assembly stations. The innovation greatly increased the pace of manufacturing, and factory owners in other industries quickly adopted the technology. The moving assembly line made products cheaper for consumers but also changed working conditions by increasing the demand for cheap, unskilled labor.